How Electrical Takeoff Software Handles 80% of Your Work in 20% of the Time

- PataBid

- Sep 26, 2025

- 7 min read

Updated: Dec 7, 2025

The electrical estimating process reveals a fundamental inefficiency that plagues contractors across the industry: 80% of estimating time goes to quantity calculations that represent only 20% of a project's complexity and profit potential. For decades, electrical contractors have accepted this imbalance as an unavoidable reality, dedicating countless hours to manually counting fixtures, measuring conduit runs, and calculating wire footage from blueprints. This labor-intensive approach to electrical takeoffs consumes valuable time that could be better spent on strategic activities that actually win projects.

The emergence of electrical takeoff software, also called electrical quote or electrical pricing software, has fundamentally changed this equation. By automating the repetitive, time-consuming aspects of estimating takeoffs, these digital tools allow contractors to reclaim the majority of their estimating hours and redirect them toward high-value activities like site analysis, competitive pricing, and client relationship building. Understanding how to leverage this technology—and when to use alternative approaches—can transform an electrical contractor's ability to compete in today's fast-paced market.

What is Electrical Takeoff Software?

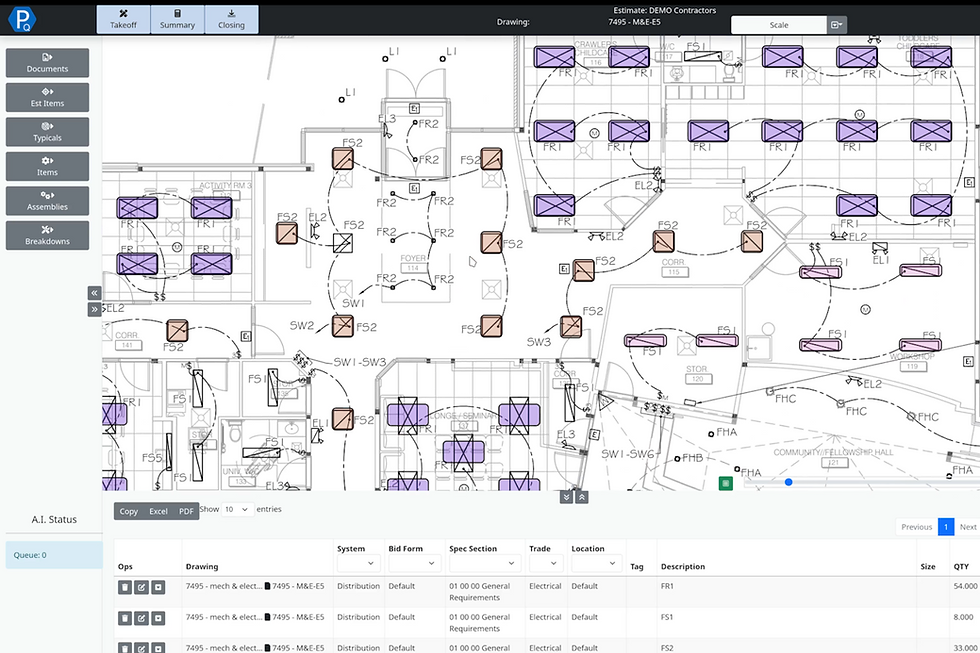

Electrical takeoff software is a specialized digital tool designed to automate the measurement and quantification of electrical components from construction drawings and blueprints. This technology serves as the foundation of modern electrical estimating by eliminating the manual processes that traditionally dominate the takeoff phase of project estimation. At its core, electrical quote software digitizes the process of identifying, counting, and measuring electrical elements from project plans. Instead of manually reviewing blueprints with rulers and tally sheets, contractors can upload digital drawings and use software tools to rapidly quantify everything from outlet counts to conduit lengths. The software maintains a database of electrical components and automatically calculates quantities based on user measurements and selections.

Modern electrical quote software incorporates advanced features that go far beyond simple measurement tools. AI takeoff capabilities can automatically detect and count electrical devices across entire plan sets, while on screen takeoff functionality allows estimators to perform complex measurements with point-and-click precision. These tools integrate with electrical take off sheets and databases to ensure consistent formatting and accurate quantity reporting. The technology handles both simple and complex electrical takeoffs, from basic residential outlet counts to sophisticated commercial and industrial installations involving multiple electrical systems. By automating the quantification process, electrical takeoff software eliminates human error in counting and measurement while providing detailed documentation of how quantities were derived.

Key capabilities include automatic scaling from PDF drawings, layer management for complex electrical plans, assembly-based takeoffs for common electrical installations, and integration with estimating software for seamless workflow from takeoff to final estimate. The result is a comprehensive solution that transforms the most time-consuming aspect of electrical estimating into an efficient, accurate process.

Top Methods for Electrical Takeoff: From Traditional to Cutting-Edge

While electrical takeoff software represents the modern standard, understanding all available methods helps contractors choose the right approach for different projects and situations. When implementing digital estimating into your business, consider factors such as project volume, team size, budget constraints, and existing workflow integration needs. Each method has distinct advantages and appropriate use cases, and successful digital transformation often involves phasing implementation based on business requirements, staff training capacity, and return on investment timelines.

Manual Paper-Based Takeoffs

The traditional approach involves printing blueprints and manually counting electrical components using rulers, calculators, highlighters and electrical take off sheets. Estimators physically measure conduit runs with architects' scales and maintain tally sheets for different device types. Despite being time-intensive, this method remains valuable for small projects, field verification, and situations where digital plans aren't available.

Best for: Small residential projects, field verification, backup verification of software results

Time factor: Slowest method, often requiring 16-20 hours for medium commercial projects

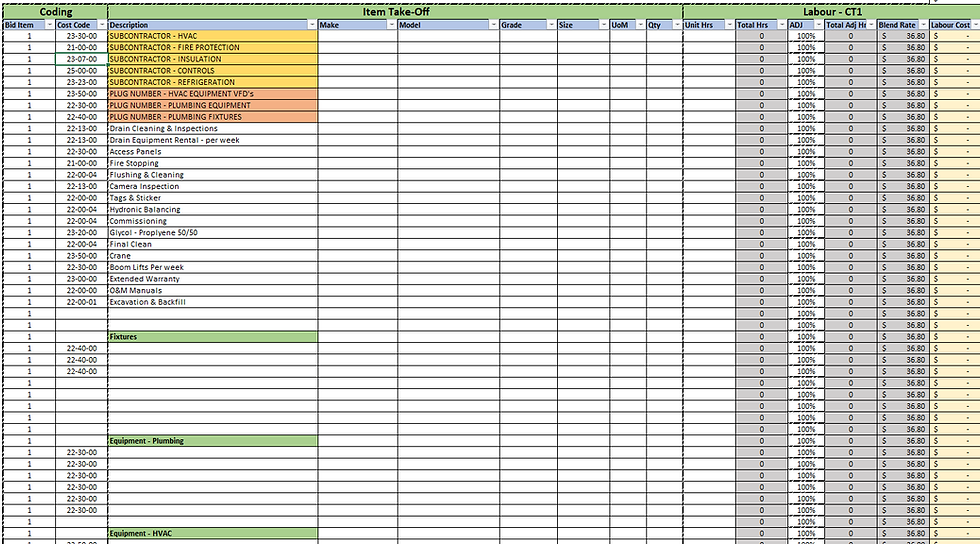

Excel-Based Electrical Takeoffs

For contractors with spreadsheet expertise, building custom Excel templates offers a middle ground between manual methods and specialized software. This approach involves creating comprehensive estimate templates that contain all commonly used materials, recent pricing data, and established installation rates. The template serves as both a takeoff tool and pricing calculator, allowing contractors to input quantities while automatically generating cost calculations. Excel can also be used for other practical tasks within the preconstruction workflow.

Excel-based electrical takeoffs require starting fresh with each project, copying the master template and customizing it for specific project requirements. While this method demands strong Excel skills to build effective templates with proper formulas and lookups, it provides complete control over the estimating process and eliminates ongoing software costs. Many contractors appreciate the flexibility to modify templates as their business evolves, though this approach lacks the automated measurement and symbol recognition capabilities found in dedicated electrical pricing software.

Best for: Tech-savvy contractors, businesses with existing Excel expertise, projects requiring highly customized pricing structures

Time factor: More efficient than manual methods but requires significant template development time

On Screen Takeoff Using Specialized Software

Dedicated on screen takeoff software provides precision measurement tools, automatic scaling, and organized quantity tracking. These platforms offer digital rulers, area calculation tools, and systematic approaches to documenting electrical takeoffs. While still requiring manual identification and measurement, they significantly improve accuracy and speed compared to traditional methods.

Best for: Medium to large projects requiring detailed documentation

Time factor: 40-60% faster than manual methods

AI Takeoff and Automated Recognition

The most advanced electrical quote software incorporates artificial intelligence to automatically identify and count electrical devices from drawings. AI takeoff technology can recognize symbols, patterns, and electrical elements across plan sets, dramatically reducing manual intervention. These systems learn from user corrections and improve accuracy over time.

Best for: Large commercial projects, repetitive project types, high-volume estimating

Time factor: 80-90% reduction in takeoff time compared to manual methods

Hybrid Approaches: Combining Methods for Optimal Results

Experienced contractors often combine multiple approaches based on project requirements. They might use AI takeoff for initial quantity capture, manual verification for critical elements, and on screen takeoff for complex areas requiring detailed analysis. This hybrid methodology maximizes both speed and accuracy. The most effective approach depends on project complexity, available time, software budget, and required accuracy levels. Large electrical contractors typically employ multiple methods, using advanced electrical takeoff software for routine projects while maintaining manual capabilities for specialized situations.

The 80/20 Transformation: How Software Changes Everything

The fundamental promise of electrical pricing software lies in its ability to flip the traditional time allocation in electrical estimating. Instead of spending 80% of time on routine quantification tasks, contractors can automate these processes and focus the majority of their efforts on strategic activities that differentiate winning bids.

The 80% That Gets Automated

Traditional electrical takeoffs consume enormous amounts of time on repetitive tasks:

Device counting (outlets, switches, fixtures, panels)

Linear measurements (conduit runs, wire pulls, cable trays)

Area calculations (lighting coverage, power density)

Assembly quantification (typical electrical rooms, standard installations)

Cross-referencing specifications with drawings

Electrical takeoff software handles these tasks in minutes rather than hours. Advanced systems can process entire floor plans, automatically identifying symbols and calculating quantities based on pre-defined assemblies. AI takeoff technology takes this further by learning to recognize project-specific patterns and adapting to different drawing standards.

The 20% Time Investment That Yields 80% of the Value

With routine quantification automated, electrical contractors can dedicate their expertise to high-value activities:

Site condition analysis and access evaluation

Installation complexity assessment

Labor productivity factor determination

Material pricing strategy and supplier negotiations

Risk identification and contingency planning

Competitive positioning and bid strategy

These strategic elements determine project profitability and win rates far more than perfect fixture counts. An estimator who understands site challenges, anticipates installation difficulties, and prices accordingly will consistently outperform competitors focused solely on accurate quantities.

Quantifiable Time Savings and Business Impact

Real-world implementations of electrical takeoff software demonstrate dramatic time reductions:

Simple residential projects: 2-3 hours reduced to 30 minutes

Medium commercial projects: 8-12 hours reduced to 2-3 hours

Large industrial projects: 20-30 hours reduced to 4-6 hours

These time savings translate directly to increased bid capacity. A contractor previously capable of estimating 10 projects per month can potentially handle 25-30 projects with the same staffing level. This capacity increase enables more selective bidding, better project targeting, and improved profitability through volume advantages.

Implementation Strategy: Maximizing the 80/20 Advantage with Electrical Pricing Software

Successfully leveraging electrical takeoff software requires more than simply purchasing technology. Contractors must restructure their estimating processes to capitalize on the time savings and redirect efforts toward strategic activities.

Choosing the Right Software Platform

Different electrical takeoff software solutions excel in different areas. Consider project types, team size, integration requirements, and budget constraints. Evaluate software based on:

Symbol recognition accuracy for your typical projects

Integration capabilities with existing estimating tools

Learning curve and training requirements

Scalability as business grows

Support quality and ongoing development

Process Redesign for Maximum Impact

Implement electrical pricing software as part of a broader estimating workflow redesign:

Standardize takeoff procedures using software capabilities

Create project-specific templates for common electrical installations

Develop quality control checkpoints to verify automated results

Train teams on both software operation and strategic estimating activities

Measure and track time allocation to ensure the 80/20 transformation occurs

Building Strategic Estimating Capabilities

Use the time saved through automation to develop competitive advantages:

Site evaluation expertise: Become skilled at identifying installation challenges

Market intelligence: Build relationships with suppliers and understand pricing trends

Client relationship development: Use faster turnaround to improve client service

Risk assessment: Develop systematic approaches to identifying and pricing project risks

The Future of Electrical Quotes

The evolution of electrical quote software continues accelerating, with emerging technologies promising even greater efficiency gains. Machine learning algorithms improve symbol recognition accuracy, while integration with BIM models enables three-dimensional takeoffs that account for complex installation routing. Cloud-based platforms enable real-time collaboration between estimators, field personnel, and project teams. Mobile applications allow for field verification and quantity adjustments during site visits. Integration with supplier catalogs and pricing databases creates seamless workflows from takeoff through procurement.

The contractors who will thrive in this evolving landscape are those who embrace the 80/20 principle: automate the routine quantification tasks and focus human expertise on the strategic elements that determine project success. Electrical quote software provides the foundation for this transformation, but the real competitive advantage comes from how contractors redeploy their most valuable resource—time—toward activities that win projects and build lasting business success. The question isn't whether to adopt electrical takeoff software, but how quickly you can implement it and restructure your estimating approach to capture the full 80/20 advantage. The contractors making this transition today are positioning themselves to dominate tomorrow's market.

Ready to Transform Your Electrical Takeoff Process?

See how PataBid Quantify's electrical takeoff software can handle 80% of your estimating work in 20% of the time. Our AI-powered platform automates device counting, conduit measurements, and quantity calculations so you can focus on winning more profitable projects.

Schedule a live demo and discover how leading electrical contractors are using our advanced takeoff tools to:

Reduce takeoff time by up to 90%

Eliminate manual counting errors

Increase bid capacity without adding staff

Focus on strategic pricing and client relationships

Comments